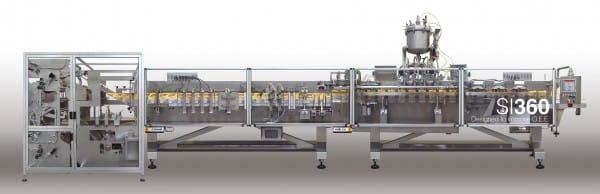

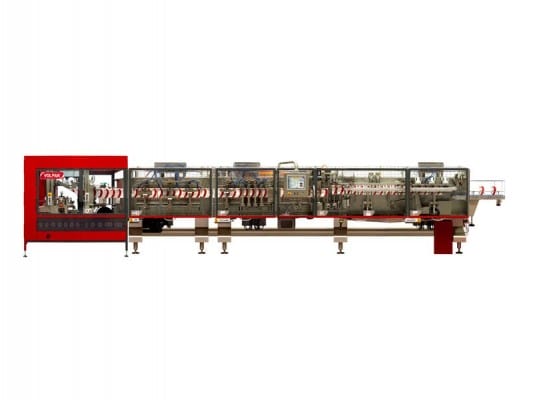

Doypack Pouch Machines

Doypack machines are advanced systems designed for packing products into flexible doypack-style pouches, known for their convenience and attractive appearance. Doypack machines perform precise pouch forming, filling, and sealing, ensuring product integrity and long shelf life. These machines offer a wide range of options, including pouches with spouts, zippers, straws, and various pouch shapes, allowing manufacturers to tailor packaging to specific market requirements.

These systems are used for packing a wide variety of food and non-food products, ensuring freshness and protection against external factors such as moisture, oxygen, and contamination. Thanks to modern technology, doypack machines deliver high output and stable packaging performance, resulting in material savings and reduced production time.

How does a doypack machine work?

The process begins with forming a pouch from film material. The pouch is then precisely opened and positioned for further handling. In the next step, the product is dosed into the pouch. With accurate portion control, every pouch contains the exact quantity specified by the manufacturer, which supports cost efficiency and process repeatability.

After filling, the machine may perform a degassing step or clean the sealing area to improve durability and final appearance. The pouch is then hermetically sealed, most commonly using thermal sealing. Depending on machine configuration, additional components can be added—such as a spout, zipper, or straw. Finally, the product may be labeled or coded and passed through quality inspection.