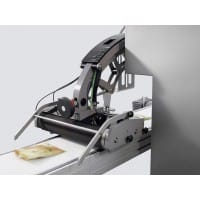

AirScan Seal Tester and Leak Detection

The unique Ishida AirScan tests the sealing of individual MAP (Modified Atmosphere Packaging) in-line. It detects holes as small as 0.25mm, at line speeds of up to 180 packs per minute.

AirScan works by lightly pressuring each pack while testing the air around it for traces of excess carbon dioxide (CO2), using laser technology.

Deviation from the specified MAP gas mix, as caused by leakage, reduces the product’s shelf-life and may damage the end-user’s relationship with the brand. It can also greatly harm the reputation of manufacturer and packer, and lead to the harsh financial penalties involved in recalls and returns.

By contrast, the fast, thorough check carried out by AirScan builds confidence that every pack dispatched to retail will reach its consumer in top condition.

Excellent results with a wide range of applications and pack types AirScan can test a diverse range of products, from fresh meat and seafood to ready meals and salads. Packaging media include trays, bags and pouches.

Unmatched speed in pack seal testing

AirScan’s unique laser technology detects traces of escaping CO2, at speeds of up to 180ppm. For most lines its speed not only meets current needs, but also offers considerable future-proofing.

Detection can cover the whole pack, or just the areas at risk

The customer can specify which parts of the pack to monitor. Top-sensing comes as standard, while side and under-sensing options can be added.

Reduced waste, improved productivity and profitability:

AirScan quickly identifies and rejects individual leaking packs, saving on labelling and secondary packaging materials. What’s more, this feedback instantly highlights sealing flaws, enabling immediate rectification and minimising losses in production and profitabilit

The certainty provided by ‘reject confirmation’

AirScan is a closed-loop inspection system. An alarm is raised if any leak detected is not successfully rejected, further increasing confidence in your output

Trouble-free integration into your existing line

An AirScan unit can readily be positioned over any available conveyor section, preferably just downstream of the sealer machine. Its speed ensures that it will never cause a production bottleneck