Trays

Dual Energy Sensor detects what other inspection systems miss

Most effective X-ray detection of low-density objects, including bone, shell, metal, glass and rubber.

Ergonomic, stainless steel design, making it easy to clean.

- Pinpoint detection of foreign bodies under 0.6mm thanks to enhanced G2 technology, from shell and stone, to metal and bone.

- Accurate X-ray inspection capable of handling packaged products with uneven surfaces, granular products and overlaps.

The DACS-GN-SE Series checkweigher is the perfect entry point for high-speed checkweighing. This model features all essential elements for a simple system that seamlessly fits your production line.

The DACS-GN-SE is available in two models depending on your factory environment, the SS model for dry environments and the WP model for wet or dusty environments.

Using patented technology, our performance-line checkweigher is engineered for weighing accuracy that meets your requirements.

The SS variant is engineered for dry environments, with a protection against ingress in accordance to industry-standard IP54 rating. It is designed for wipe-down cleaning, with aluminium conveyor beds delivering strength without providing unnecessary weight loading to the weigh cell.

A multihead weigher or computer combination weigher (CCW) is an industrial weighing machine which delivers highly accurate, reliable and high speed weighing of food and non-food products.

Ishida has offered virtually every known CCW application solution.

The multihead weigher was invented and developed by Ishida in the 1970s. Since then Ishida has provided weighing equipment for thousands of food and non-food applications with more than 50,000 machines installed.

Machine for the packaging of products in different materials: wrap around packaging, trays, plateau packs and cardboard boxes. When used in combination with the lidding module, it can also create packages with tray and lid, both internal and external.

Either flat or standing products can be packaged depending on the configurations and arrangements. Special applications are available upon request. The machine envisages conformity checks on incoming products and outgoing packaging.Extremely compact and versatile, the WR features great multifunctionality. Large capacity, easy-to-load carton store. Highly accessible, ergonomic and user-friendly thanks to the large HMI panel.

The machine comes standard with a hot-melt package closing module, however, it can also be fit with taping module that integrates seamlessly into the machine body. The WR-S-E can be fit with automatic format change and numerous accessories to increase the degree of customization to meet your needs.

The Skilled 504 is an electro mechanical robot with articulated cinematic structure type SCARA with 4 interpolated axes, and a working area of 360°. Our first SCARA robot (Selectively Compliant Assembly Robot Arm) was launched in the market in 1996 and since then it has been installed in over 1000 plants worldwide. Thanks to its high flexibility and possibility to customize the pick-up tool for illimitated range of applications (cardboard boxes, bundles, heat-shrunk trays, bags, cans, reels, etc.), the Skilled 504 has been used to solve a wide variety of end-of-the-line product handling problems in the most diverse plant logistic situations. Its friendly and powerful programming method has been developed in Visual Basic completely by our engineers on the basis of 30 years experience in the palletizing field, in order to quickly carry out any kind of personalization at any time.

Ideal for palletising multiple lines.

- Clever design to work also in a narrow working area

- Payload 120 kg including gripper

- 4 axes

- 800 cycles/hour

The SATURN S4 wrapper has been designed to cover the markets with medium productions, up to 60 pallets / hour, being the best alternative to the arm wrapping machine.

The SATURN S4 wrappers equip the best technology available on the market, as well as the rest of our models with higher productive capacity, with electronic tension control and self-adjusting according to the load profile, which prevents film breakage or deformation of the load, ensuring maximum stability with the minimum film consumption.

The automated vertical warehouses use mechanical structures moving between two rows of racks to carry out the load AS/RS (storage / retrieval) operations.

The stored containers are trays whose features and dimensions are determined by specific characteristics of the goods.

The whole structure is fully enclosed by walls and therefore isolated from the company surrounding environment; the only openings are one or more “bays” through which the trays are set available by the system.

The handling operations are controlled by software through the appropriate station placed next to the bay.

Designed to handle larger products, you can now have the benefits of a high-speed checkweigher for your boxes and cartons.

The specialist Carton Line checkweigher offers impressive belt speeds and weighing accuracy as granular as 1g, to give you the quality assurance you desire.

This model is also supplied with a remote RCU tower for correct product positioning, as well as a variety of customisable features to suit your exact needs.

The PB model is engineered for dry environments with a protection against ingress in accordance to industry-standard IP30 rating.

The Ishida QX-1100 Tray sealer has been recognised as a major step forward in smart tray sealer design, with its use of advanced servo-technology, its intuitive interface and its open, accessible design. Today, the QX-1100 is available in three different confi gurations, ensuring a close fi t to the types of products you pack, the volume you want to achieve and the frequency of product or tray-type changeovers. For all three confi gurations:

- Sealing is a high-speed, high-precision operation delivering top-fl ight appearance and functionality across all pack types, including skinpack and slicepack

- Selected sealing heads can be excluded (e.g. in the event of a knife or heater issue). Trays are automatically re-routed and production can continue under circumstances that would cause delays with conventional tray sealers

- Operators of all skill levels fi nd the QX-1100 easy to set up and operate

- Thorough cleaning is quick and simple, with quick-release or simple lift-off of parts and rapid self-draining of washdown solutions

- Tool-swapping is largely automated, reducing manual handling during changeover

- Sophisticated inbuilt quality control means fewer RTMs (returns to manufacturer)

The unique Ishida AirScan tests the sealing of individual MAP (Modified Atmosphere Packaging) in-line. It detects holes as small as 0.25mm, at line speeds of up to 180 packs per minute.

AirScan works by lightly pressuring each pack while testing the air around it for traces of excess carbon dioxide (CO2), using laser technology.

Deviation from the specified MAP gas mix, as caused by leakage, reduces the product’s shelf-life and may damage the end-user’s relationship with the brand. It can also greatly harm the reputation of manufacturer and packer, and lead to the harsh financial penalties involved in recalls and returns.

By contrast, the fast, thorough check carried out by AirScan builds confidence that every pack dispatched to retail will reach its consumer in top condition.

Excellent results with a wide range of applications and pack types AirScan can test a diverse range of products, from fresh meat and seafood to ready meals and salads. Packaging media include trays, bags and pouches.

Skilled LGV (Laser Guided Vehicle) is an automatic fork lift truck which, together with our palletizing systems, allows complete “end of line” automation. This results is cost savings and significant improvements in production management.

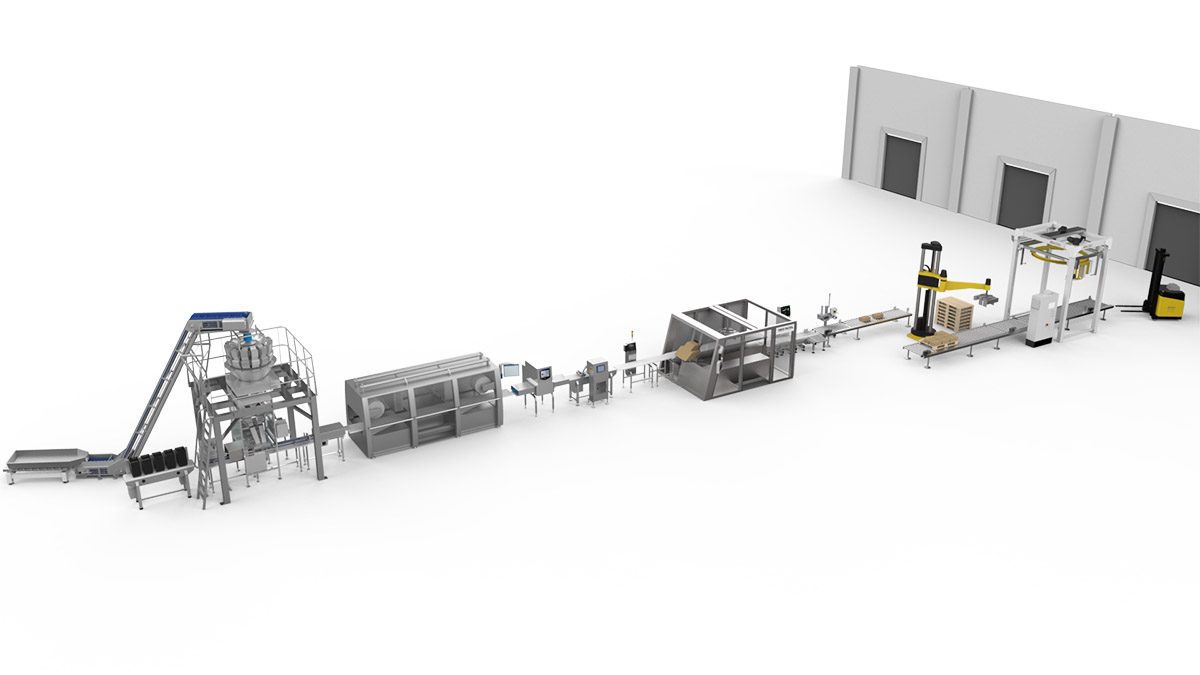

Znamy się na tworzeniu niezawodnych i indywidualnych rozwiązań zwiększających efektywność pracy zakładów i fabryk. Specjalizujemy się w kompletowaniu poszczególnych elementów linii do produkcji tacek. Przykładowy skład linii:

-

Przenośnik typu łabędzia szyja służy do przenoszenia towarów na wysokość niezbędną do dalszego przetwarzania. Cechuje się dużą przepustowością oraz możliwością pracy z delikatnymi produktami.

-

Kolejnym elementem linii jest naważarka wielogłowicowa wspomagana komputerowo. Obsługuje towary z największą precyzją oraz wysoką prędkością operacyjną.

-

Zgrzewarka traysealer o imponującej funkcjonalności dedykowana jest opakowaniom typu skinpack oraz slicepack. Nadaje się zwłaszcza do dużych cykli produkcyjnych, zgrzewając nawet 100 tacek na minutę.

-

Do wykrywania elementów obcych (szkło, kości, guma, metal) służy technologia X-ray “Dual Energy” Sensor. Sprawdzi się w przypadku towarów opakowanych. X-ray wykrywa ciała obce takie jak np. aluminium w tacce lub formie aluminiowej oraz gdy produkty w opakowaniu zachodzą na siebie.

-

Tester szczelności wykorzystuje technologię laserową, lokalizując nawet najmniejsze otwory w paczkach. Dzięki temu mamy pewność, że każde opakowanie z atmosferą ochronną MAP wysyłane do sprzedaży detalicznej, dotrze do klienta w doskonałym stanie

Linia do produkcji tacek składa się także z wagi kontrolnej. Model WP przeznaczone jest do pracy w warunkach zakurzonych i mokrych, a model SS – suchych. W zakładach przetwórstwa spożywczego nie może również zabraknąć maszyny pakującej pozwalającej na tworzenie opakowań zarówno z tacą, jak i wewnętrznym lub zewnętrznym wiekiem. Pracę linii technologicznej wspierają również elektromechaniczny robot, owijarka paletowa oraz automatyczne wózki widłowe. Magazynowanie towarów odbywa się w płaszczyźnie pionowej, a w realizacji poszczególnych czynności pomagają konstrukcje wykonujące polecenia odkładania i pobierania.

W przypadku linii produkujących do tacek liczy się nie tylko wydajność, ale także bezpieczeństwo obsługi. Fenix Systems spełnia najwyższe standardy w każdym zakresie. Po więcej informacji zapraszamy do kontaktu. Dostosujemy rozwiązanie do Twoich indywidualnych potrzeb.