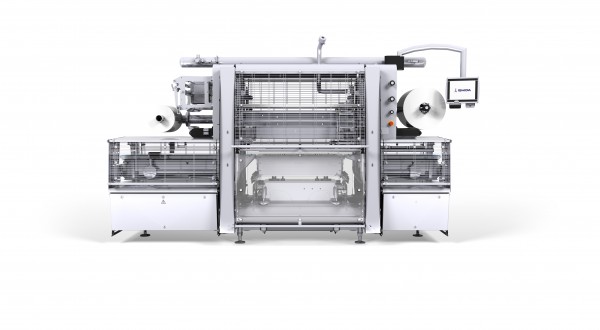

QX-1100-Flex Tray Sealer

The Ishida QX-1100 Tray sealer has been recognised as a major step forward in smart tray sealer design, with its use of advanced servo-technology, its intuitive interface and its open, accessible design. Today, the QX-1100 is available in three different confi gurations, ensuring a close fi t to the types of products you pack, the volume you want to achieve and the frequency of product or tray-type changeovers. For all three confi gurations:

- Sealing is a high-speed, high-precision operation delivering top-fl ight appearance and functionality across all pack types, including skinpack and slicepack

- Selected sealing heads can be excluded (e.g. in the event of a knife or heater issue). Trays are automatically re-routed and production can continue under circumstances that would cause delays with conventional tray sealers

- Operators of all skill levels fi nd the QX-1100 easy to set up and operate

- Thorough cleaning is quick and simple, with quick-release or simple lift-off of parts and rapid self-draining of washdown solutions

- Tool-swapping is largely automated, reducing manual handling during changeover

- Sophisticated inbuilt quality control means fewer RTMs (returns to manufacturer)

Ishida QX-1100 Single Lane

QX-flex range

High production throughput, especially suitable for larger tray sizes

This single-lane version of the QX-1100 Flex can seal large trays (up to 400mm in width), up to seven at a time. At 15 cycles per minute, this means an impressive throughput of up to 100 trays per minute, making it particularly suitable for large production runs.

Ishida QX-1100 Twin Lane

Fastest tray sealing speeds available, delivering maximum capacity Designed for medium-sized and small trays, this twin-lane version, with its maximum of 14 sealing heads, can achieve speeds of up to 200 trays per minute, the fastest in the industry. The QX-1100 Twin Lane thus allows you to achieve phenomenal returns on floor space.

Ishida QX-1100 SDL (Split Dual Lane) Extraordinary versatility and speed for complex or varying product ranges Where you have a high overall throughput but great variety in run-length and more than a few different products to pack, the SDL offers you a unique opportunity to really get the maximum out of your floorspace. Each lane of this unique machine can run completely independently of the other, with different speeds, separate products, trays, films, pack atmospheres and target weights. You thus have two tray sealers, each fast and highly versatile, running within the footprint of a single machine: an immediate space saving of 50%!

Integrated gas mixing, analysing and coding Integrated systems produce exactly the specified gas mixture, then rigorously monitor it.

Rapid changeovers and washdown

Automatic and quick-release features plus self-draining design ensure rapid cleaning and changeovers

Flexible by design The QX-1100 can be optimised to suit all product types, trays and film materials.

QX 1100

These three QX-1100 Flex models use advanced servo-technology to bring you the best in smart, hygienic tray sealer design, whether your requirement is maximum speed and throughput for large or small trays, or maximum return on floorspace.